Ensuring Safety: The Role of Gas Detector Calibration Machines in Regulatory Compliance

The Importance of Gas Detector Calibration

Gas detectors are essential safety devices used in various industries to monitor and detect the presence of hazardous gases. These devices are crucial for ensuring the safety of workers and the environment, as they provide early warnings of potential gas leaks or buildup. However, to maintain their accuracy and reliability, regular calibration is necessary. Calibration involves adjusting the gas detector to ensure it provides accurate readings. This process is vital because even slight inaccuracies can lead to dangerous situations, such as undetected gas leaks. Regular calibration helps in maintaining the device’s precision, ensuring that it functions correctly and provides reliable data. In industries where hazardous gases are present, the consequences of inaccurate readings can be severe, making calibration an indispensable aspect of safety management.

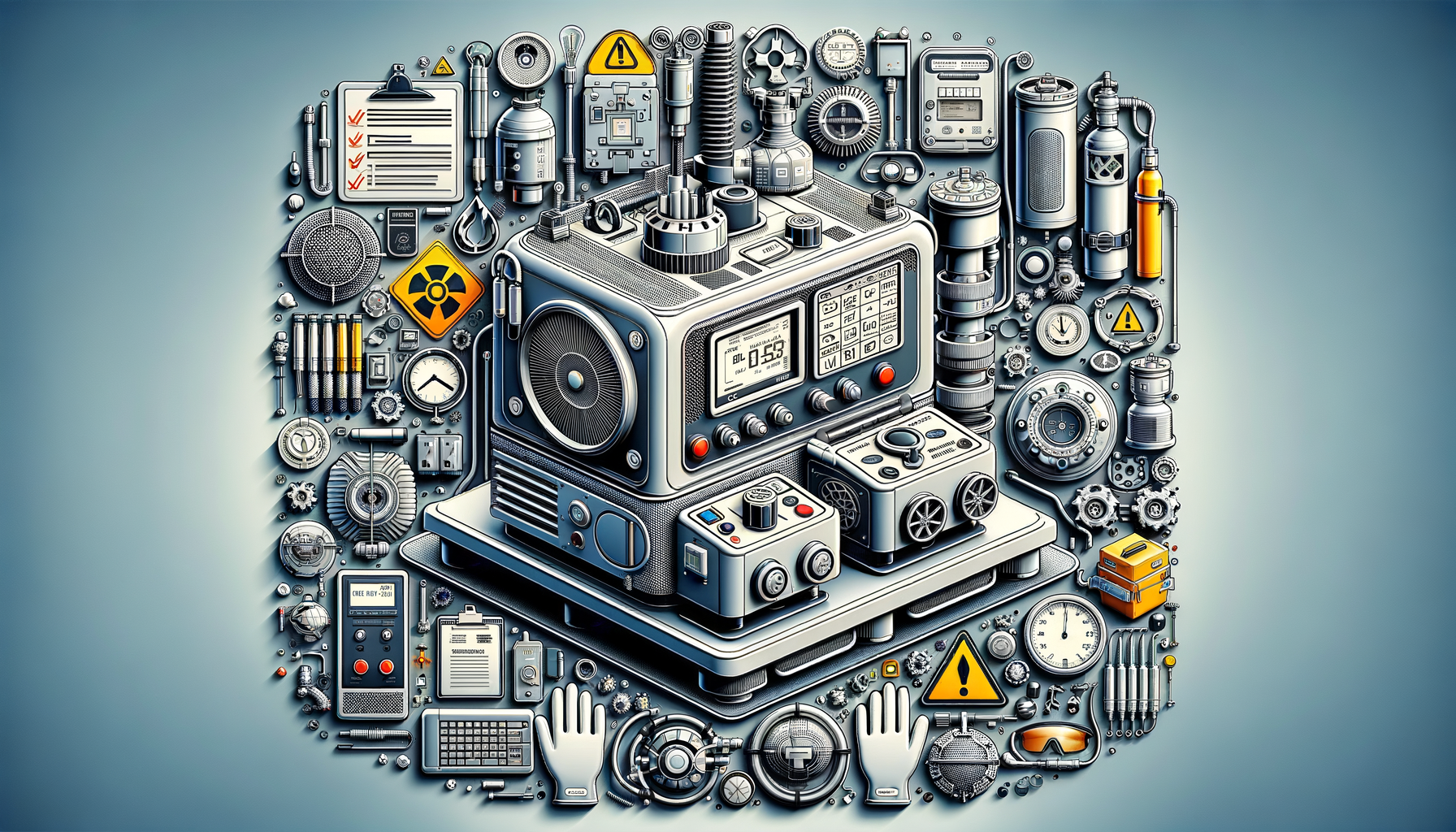

Understanding Gas Detector Calibration Machines

Gas detector calibration machines are specialized devices designed to calibrate gas detectors efficiently and accurately. These machines automate the calibration process, reducing the chances of human error and ensuring consistency in calibration results. They work by exposing the gas detector to a known concentration of gas and adjusting the detector’s readings to match the known value. This process ensures that the gas detector provides accurate readings when in use. Calibration machines come with various features, such as automated calibration sequences, data logging capabilities, and compatibility with different types of gas detectors. By using these machines, industries can ensure that their gas detectors are always in optimal working condition, thereby enhancing safety and compliance with regulatory standards.

Safety and Regulatory Compliance

Regulatory compliance is a critical aspect of industrial operations, particularly in sectors where hazardous gases are present. Various regulations and standards govern the use and maintenance of gas detectors, emphasizing the importance of regular calibration. Compliance with these regulations not only ensures the safety of workers but also protects companies from legal liabilities. Gas detector calibration machines play a crucial role in helping companies meet these regulatory requirements. By providing accurate and reliable calibration, these machines ensure that gas detectors function as intended, thereby reducing the risk of accidents and ensuring compliance with safety standards. In addition, maintaining a regular calibration schedule as per regulatory guidelines demonstrates a company’s commitment to safety and regulatory adherence.

Benefits of Regular Calibration

Regular calibration of gas detectors offers numerous benefits, both in terms of safety and operational efficiency. Firstly, it ensures the accuracy of gas detection, which is critical for preventing accidents and ensuring the safety of personnel. Accurate gas detection allows for timely responses to potential hazards, minimizing the risk of exposure to harmful gases. Secondly, regular calibration helps in extending the lifespan of gas detectors by ensuring they operate within their specified parameters. This reduces the likelihood of false alarms or missed detections, which can lead to costly downtime or repairs. Additionally, regular calibration supports compliance with industry standards and regulations, which is essential for maintaining operational licenses and avoiding penalties. Overall, the benefits of regular calibration make it a worthwhile investment for any industry relying on gas detection systems.

Choosing the Right Calibration Machine

Selecting the appropriate gas detector calibration machine is crucial for ensuring effective calibration and maintaining safety standards. When choosing a calibration machine, several factors should be considered:

- Compatibility: Ensure the machine is compatible with the types of gas detectors used in your facility.

- Automation: Look for machines that offer automated calibration processes to reduce manual intervention and errors.

- Data Logging: Machines with data logging capabilities can track calibration history and provide valuable insights into detector performance.

- Ease of Use: User-friendly interfaces and clear instructions make the calibration process more efficient and accessible.

By considering these factors, industries can select a calibration machine that meets their specific needs and enhances their safety protocols. Investing in a high-quality calibration machine is a proactive step towards ensuring the safety and reliability of gas detection systems.